DATA ARCHIVING

and REMOTE CONTROL

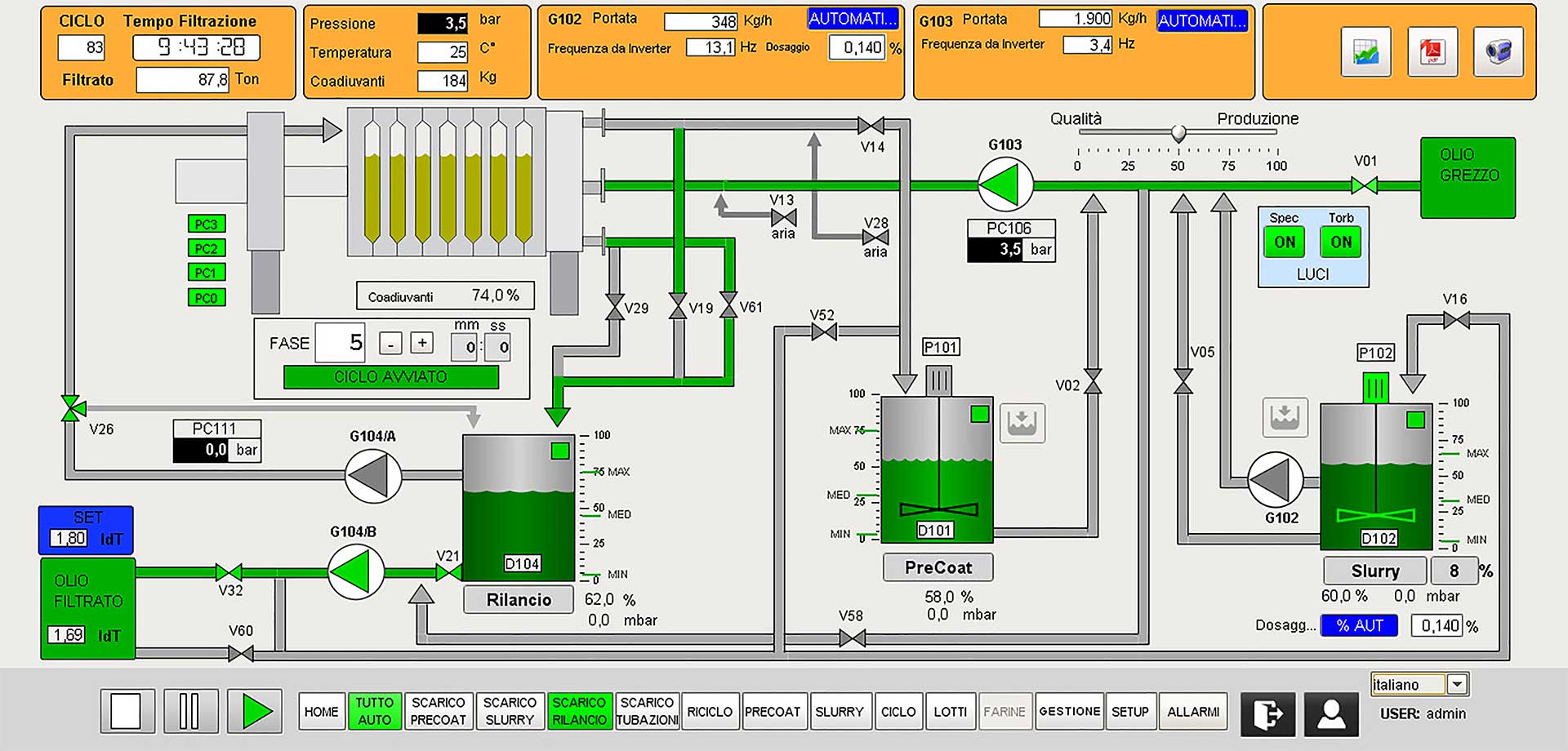

Windows Personal Computer with ExoosPROLite software for:

– memorizing and archiving informations related to filtered oils and the parameters of each filtration cycle

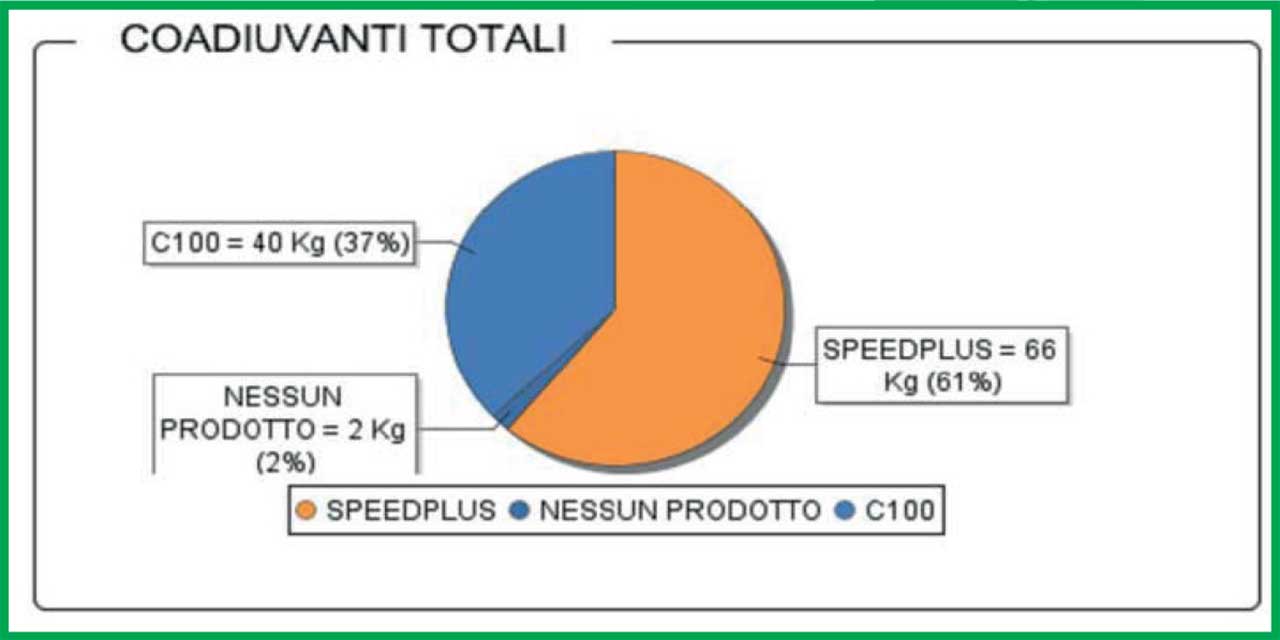

– archiving information relating to the adjuvants used

– controlling and commanding the system remotely, via personal computer, smartphone or tablet.

OUTPUT

TURBIDITY CONTROL

A camera acquires images from the sight glass.

The ExoosPROFull software processes the information and ensures that only oil compliant to the turbidity set by the operator is sent to finished oil storage tanks.